Cast Iron Radiators

A carefully curated range of styles, an unrivalled range of finishes. Custom sizing up to 2.5m long. Made to order in Manchester, UK, and delivered in 7-8 weeks.

Our new Radiator Finder tool lets you filter by style, size, and required heat output, making it easy to narrow down the options that work for you.

Made to order, built to last

Request A Free Brochure

Inside our Product Brochure you’ll find full technical details to help you choose the right radiator for you. We’ve packed in as much in situ photography as possible, showing options for sizing and finishing your radiators, along with our most popular valves and brassware, to give you the best idea of just how customisable our radiators are.

Every radiator we produce is made to order, so we don’t include prices in the brochure. For guide pricing, see the average costs table below. Alternatively use our online radiator builder tool or call our team on 0161 439 9350 who will help you create your bespoke radiator quote.

Request a digital brochure by clicking the button below, or order a physical copy directly.

Where do I start?

Begin by calculating the heat output you need for each room using our calculator. You will then have a figure given in British Thermal Units (BTUs) which can be provided by one single radiator or divided across several radiators within the room. Available space, location of windows and any existing pipe-work you are working with will all impact the number, size and placement of your radiators.

For help with calculating your BTUs consider booking an one-to-one consultation, where one of our team can walk you through the process in person or virtually.

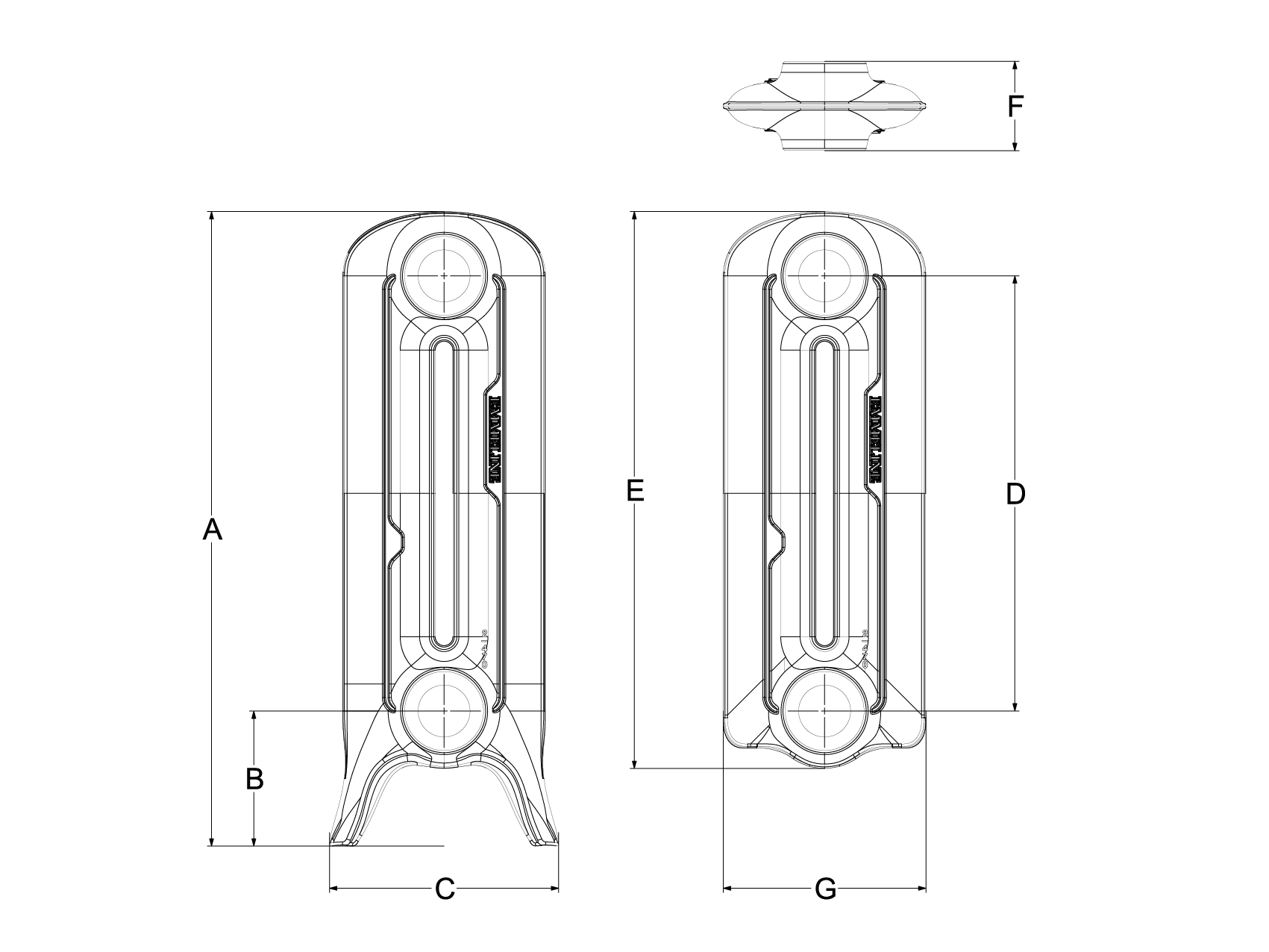

Image: The Emmeline I 465mm finished in Paint and Paper Library’s Truffle.

-768x512.jpg)

Ordering Your Cast Iron Radiator

Our Radiator Builder makes it easy to build, name and keep track of multiple radiators across several rooms.

First select your model, depth, height and number of sections. Choose a paint or polish from our Bare Metals or Signature Collection. We also offer any branded colour from Farrow & Ball, Little Greene or Benjamin Moore, to name a few. Then decide on wall-mounted or floor-standing, and finish with your choice of valves and accessories.

Alternatively, use our Radiator Finder tool to filter by style, size, and heat output to quickly see what fits.

Explore the Builder + Finder

Image: The Grace 4 column 760mm finished in Anthracite.

How will my cast iron radiators be delivered?

We offer free delivery by pallet network. Cast iron radiators arrive packaged on a pallet and are set down outside the property but are not brought into the house.

For an additional charge, within Greater Manchester and Greater London, we can provide a two-man delivery service, which allows us to unpack the radiators, bring them into your home and place them into position ready for installation.

We take the utmost care to deliver a product that will heat your home for decades to come. Our guarantee ensures that our non-electrical products, including steel and cast iron radiators, radiator valves, wall stays, tools and component parts are free from manufacturing defects for 25 years from the date of delivery.

Read Our Terms And Conditions

Image: The Mercury 4 Column 360mm finished in Paint and Paper Library’s Muga.

-768x676.jpg)

Are cast iron radiators heat-pump compatible?

Just because cast iron radiators were born in the coal-fired Victorian era does not mean they are stuck there. All of our models are compatible with heat pumps and other renewable energy sources.

In fact, air and ground source heat pumps produce low-frequency heat cycles in a very similar way to the coal boilers that cast iron radiators were originally designed for – both are slow to warm up and slow to cool down.

The high thermal mass of cast iron paired with the large surface area and high internal volume of a sectional radiator design are features that made them run well on coal. The same features make them equally well suited to the slower heat cycles and lower water temperatures you get with a heat pump.

How much do cast iron radiators cost?

The prices below are averaged across our entire range. They include the cost of the cast iron radiator and all accessories required for installation.

| Signature Collection | Farrow & Ball or Little Greene | Bare Metal | |

| Small Radiator | £750 | £800 | £1,150 |

| Medium Radiator | £975 | £1,150 | £1,575 |

| Large Radiator | £1,200 | £1,500 | £2,000 |

A three bed house typically requires about 12 radiators costing an average of £10,000 to £18,000 dependent on finish.

If you have inquiries or seek precise pricing details, feel free to reach out to our team. Contact a staff member to request a customized quote.

Contact Us

Image: The Grace 4 Column 500mm finished in Farrow and Ball’s Black Blue.

The Old Radiator Company

Rooted in architectural salvage, our company owes its essence to time-tested veteran products. Today, our mission is to seamlessly integrate these classics into the modern world, outfitting them with thermostatic valves or incorporating them into heat pump systems. Models such as Emmeline and Mercury, our newest additions, draw significant inspiration from revered classics, paying homage to the giants of the past.

Our sister brand, The Old Radiator Company, is dedicated to restoring and rehoming antique radiators, ensuring these remarkable pieces of history remain relevant for generations to come. Every reclaimed radiator is expertly restored and compatible with modern thermostatic valves and heat pumps.

Visit The Old Radiator Company

Image: The Circular Perfection Radiator made by the American Radiator Company finished in Matt Black.

-300x200.jpg)