Calculate Your Required Heat Outputs

The heat loss of each room is affected by factors such as size, building materials and the type and dimensions of the doors or windows. Our calculator is MARC approved and makes easy work of figuring out your needs so you can start building your radiators.

Try It Out-768x512.jpg)

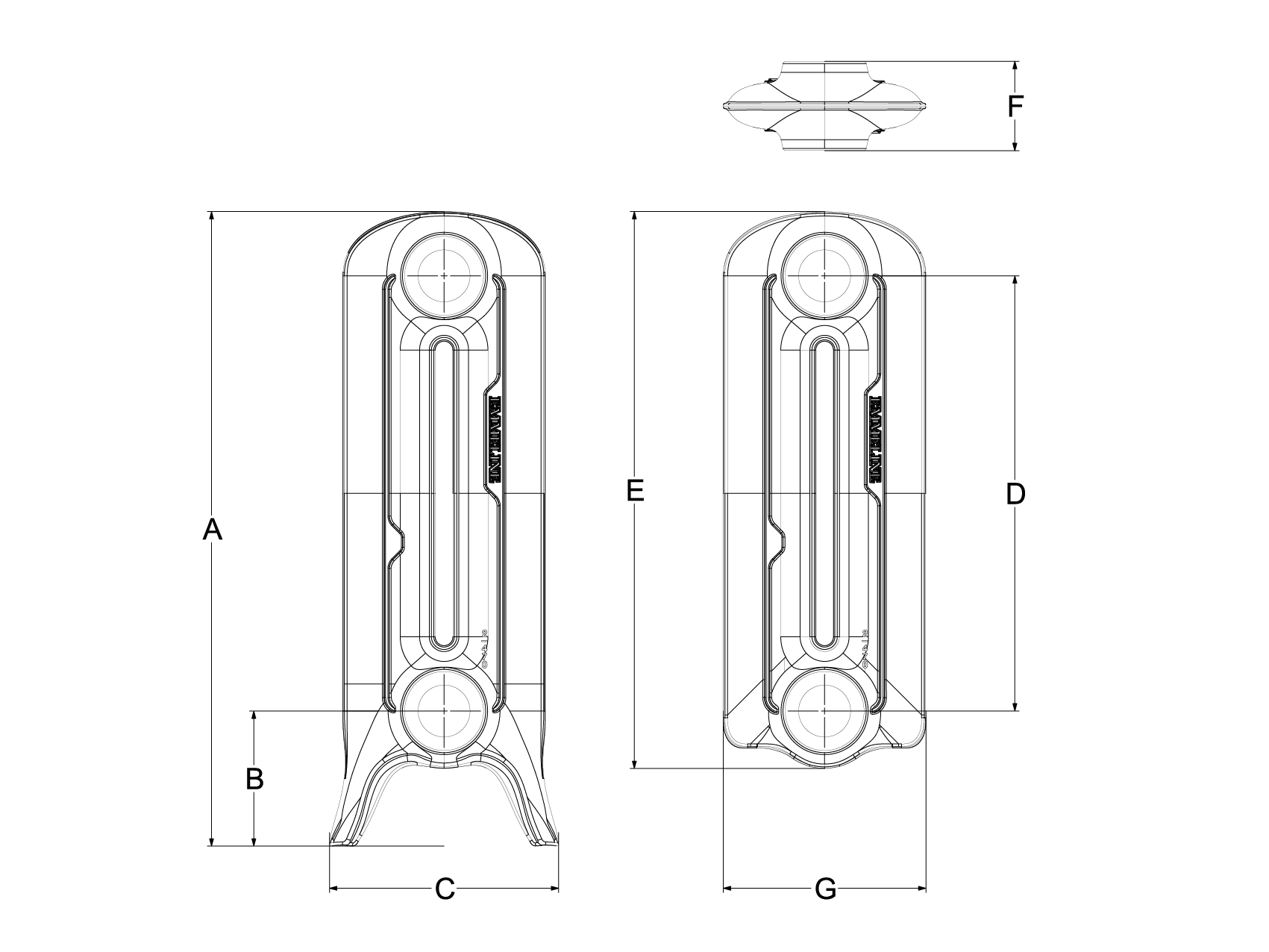

Technical Drawings

Every radiator, every measurement, every file format. Free to download for everyone.

Find A Technical Drawing

Heating History, From Kew Gardens To The Empire State

Two hundred years in development, read about how central heating and the cast iron radiator came to be.

Explore The Timeline

Thread Sizes Guide

All of our replacement end bushes for DIY radiator restorations plus help with measuring thread sizes and identifying the correct types of end bush.

View Thread Sizes Guide

Panel Radiator Outputs Calculator

When upgrading your steel panel radiators to column radiators, it’s useful to know how much heat they are currently providing. Our calculator makes it quick and easy.

Go To Calculator

-300x200.jpg)