We are cast iron specialists

Castrads is a family business founded in 2006. We started out as a small team, assembling and painting radiators on a farm in rural Cheshire. Today we employ about 65 people in four countries.

Our manufacturing base and headquarters remains in Greater Manchester. We also have showrooms in London and New York, and an assembly and finishing plant in Poland that serves our EU customers.

We are cast iron specialists: our core product is and always will be cast iron radiators.

Our Ethos and Culture

Our mission is to produce elegant radiators that last for centuries, building on foundations laid by the pioneering engineers who came before us.

We have modernised our controls and use kevlar gaskets rather than asbestos, but the fundamental construction of a cast iron radiator hasn’t changed in 140 years. To our mind it is the original and best.

Our company culture can be distilled into just four words: quality, respect, humility and elegance. We stand for the circular economy, equal opportunities and dignity in the workplace. We are proud to be Living Wage employers with a gender pay balance that favours women.

Our Story

Castrads was set up by Chris Baylis and is now run by his two sons, Nick and Adam. Before Castrads, Chris ran an architectural salvage business called RBS. He’s been at the intersection of interiors and recycling since 1986.

From the reclamation yard, Chris and his young sons, who helped out on Saturdays, developed a great reverence for the original cast iron radiators made by the likes of the American Radiator Company, Crane, Beeston, Bundy and more. Castrads was born out of respect for the exquisite engineering developed in the pre-war radiator industry.

Our Product

Today we are, to our knowledge, the only business in Britain actively investing in new casting techniques that further the technology of cast iron radiators.

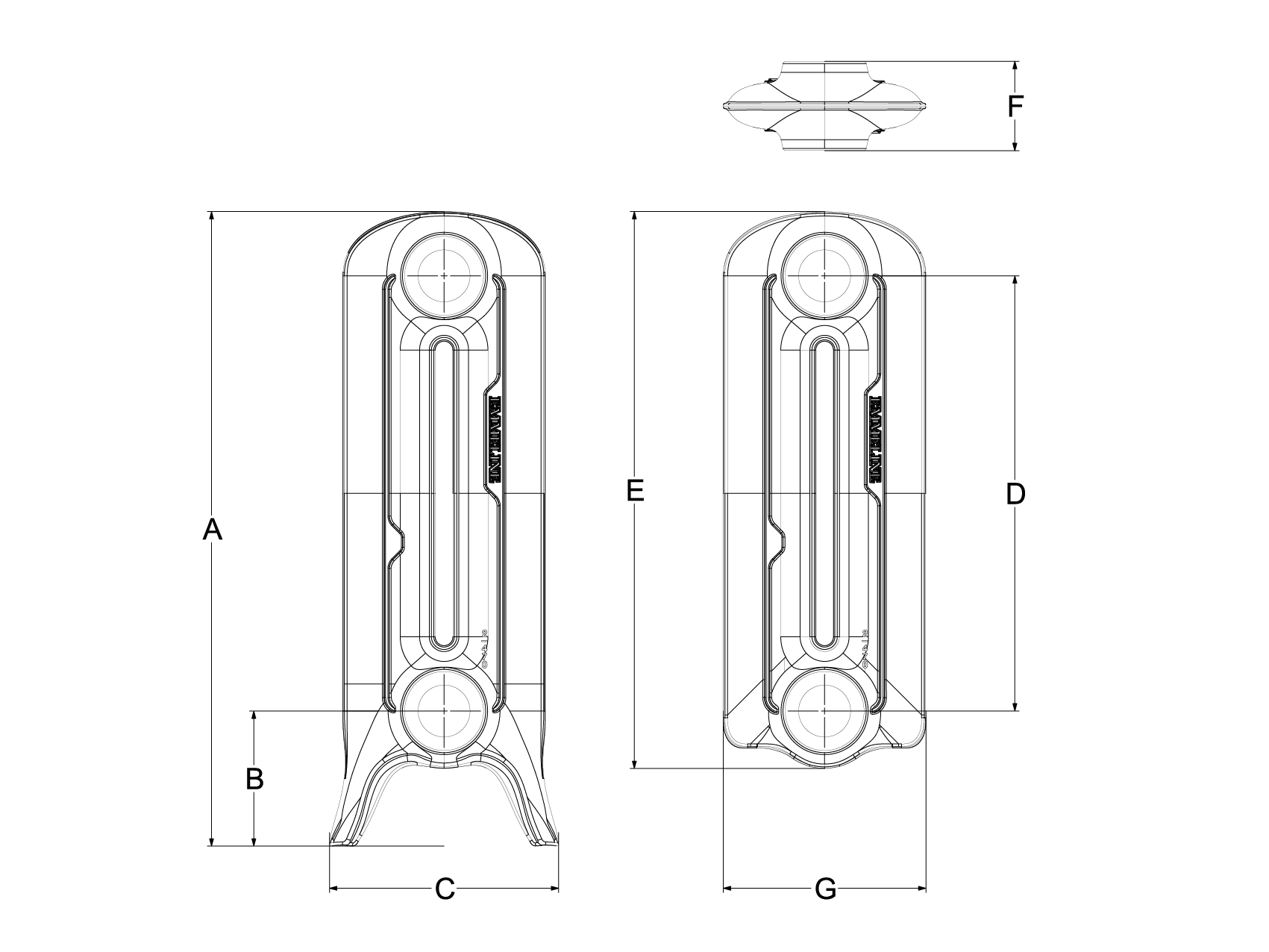

Our dedicated Product team (pictured) have designed our Emmeline and Mercury ranges from the ground up. A third new range, Celeste, will be launching soon.

We are proud to have brought the manufacture of many of our components into Britain. Several are produced in the Black Country, England’s industrial heartland.

Order Brochure

Our People

In 15 years, Castrads has grown into a company of 65 employees based across the UK, America and Poland. Many have been with us since the very early days.

To quote our COO, Adam, “We have some of the best people in our team at Castrads. I see it every day in the quality of their work and the care they extend to our customers.”

Our customers trust our specialist knowledge and that isn’t limited to the factory floor. Sales training covers our own made-to-measure product, a broad range of heating systems and even hands-on production sessions at Castrads HQ where our salespeople assemble radiators from scratch.

Our Impact

Recycled and recyclable

We believe that climate change is the biggest single issue facing humanity today. We are committed to reducing greenhouse gas emissions in our processes. Cast iron is a circular material: our radiators are made of scrap metal that is melted in electric furnaces.

Built-in longevity

We regularly recondition century-old radiators, and our own are built to last just as long. This means the embodied carbon of a cast iron radiator is significantly lower than that of a steel panel one designed to be replaced after just 15 or 20 years. There is, however, much more that we can do.

Read about our refurbishment service

Reducing our footprint

At our HQ in Manchester, we are powered by 100% renewable electricity with 30% of that generated by on-site solar. We recycle the water in our testing process and all our waste metal and grinding dust. We are working on removing all single-use plastics from our packaging and production processes.

Action for the future

In the next three years we will electrify our fleet of vehicles, move away from the gas-powered infrared ovens that we use for curing our paint in favour of electric, improve the insulation on our premises and move toward heat pumps and away from the gas boilers that we currently use to heat our buildings.

-300x200.jpg)