One-Pipe Steam

Showing all 6 results

Showing all 6 results

Steam Heat Means Cast Iron

All our cast iron radiators work perfectly on steam heat. Browse our complete range of British-made cast iron radiators.

Browse All Cast Iron RadiatorsOne-Pipe Steam Heating

You’ll know it from the hiss

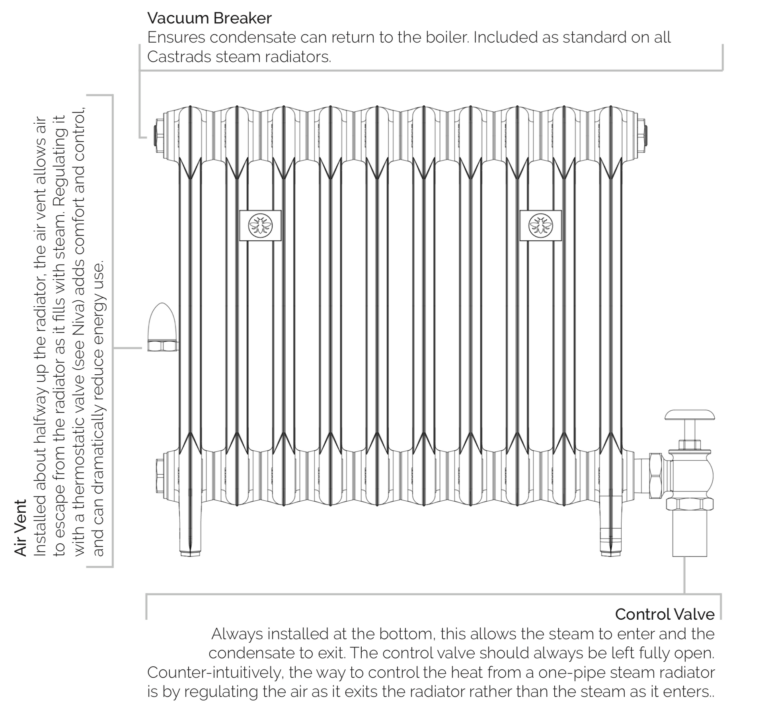

In one-pipe steam installations, steam flows from the boiler to the radiators, forcing air out through a vent on the radiator. This air vent closes automatically when the radiator is full of steam. The heat energy in the steam warms the room. As this occurs, the steam loses its energy, cools and condenses into water which pools at the bottom of the radiator. This condensate then flows back to the boiler again through the same single pipe.

Due to the steam and water flowing in opposite directions through the same pipe, the diameter of this pipe is typically more than 1″. One-pipe radiators are easy to identify from the single, fairly large pipe connected to them, always at the bottom, and an air vent attached to the opposite side, typically about halfway up the height of the radiator.

How to recognize a one-pipe steam radiator

The inlet, or control, valve must have a large internal bore: minimum of 1″ for radiators of 5000 BTUs or fewer; at least 1-¼” above that. On a one-pipe steam radiator it must be fully open or fully closed. Throttling the valve (leaving it halfway open) can lead to very noisy steam hammer. The heat from a single-pipe steam radiator is controlled by restricting the air that can exit.

Steam vents control the flow of heat into the radiator by throttling the air that exits. This occurs by the means of a thermostat in the valve which will close when it reaches temperature at 212 °F.

Adding a thermostatic valve between the radiator and air vent allows for a greater degree of control, by stopping steam flowing into the radiator at temperatures lower than the steam vent. Thermostatically-controlled steam radiators require a vacuum breaker to ensure the condensate can always return to the boiler. Ours are supplied with one as standard.

Which radiators to use with one-pipe steam?

Cast iron really is the time-proven material of choice for steam heating. Steam puts the system under a lot of stress: large temperature swings that cause the metal to expand and contract with every heating cycle; acidic conditions; and, if the system isn’t well designed or maintained, intense shocks from steam hammer. All of this goes against using thin-walled steel radiators with welded joins, they just don’t last.

We only offer cast-iron radiators for steam systems, never steel. When it comes to valve connections on steam, we only recommend threaded, mechanical joins with steel or brass pipe. While compression fittings are perfect for hydronic systems, we prefer the time-tested, heavy-duty security of a threaded join.

-768x512.jpg)

-300x204.jpg)